Build a process control room - JST Jungmann offers you the perfect solution. Can we inspire you?

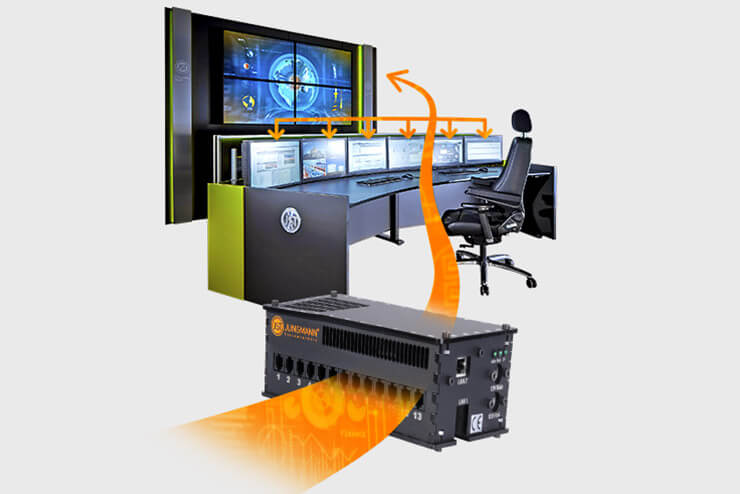

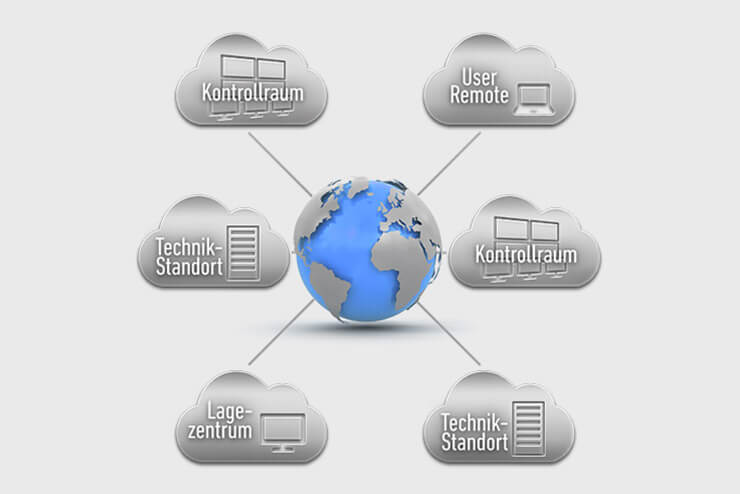

Are you looking for a professional partner for the construction of your process control room? Then JST is perfect for you. Since 2001 we have been implementing well thought-out and technically innovative process control rooms for a wide range of industries right down to the last detail. Our solutions are developed individually to meet specific needs and architectural constraints. We are always on the cutting edge of technology and are passionate about developing our own outstanding professional tools, which are only available at JST. Such as our PixelDetection®. It works away reliably in the background acting as a watchful eye of the operator and emits an alarm at the right moment. We would like to invite you to personally experience the full range of our services in our control room simulator. You will be thrilled!

OFFER BUILD PROCESS CONTROL ROOM

-

Analysis and planning of your process control room.

-

Everything from a single source: architecture, technology, light, acoustics, climate.

-

Modern monitor walls for 24/7 operation

-

Ergonomic process control room furniture from Germany.

-

Stress-free and efficient operation.

-

Pleasant working atmosphere for optimum performance.

Practical examples: Building process control rooms

Industry and public utilities rely on JST technology for their process control rooms in 24/7 continuous operation. The highest safety regulations apply here. High demands are also placed on the employees. Because no alarm can be allowed to escape their watchful eyes, considerable harm can quickly be done in an emergency. JST knows the requirements and knows which hardware and software solutions you need to have everything perfectly under control. Our enthusiastic customers will give you an insight into our joint projects here. Browse through our references. We are confident that there is a completed project that fits your requirements.

We will be happy to put you in touch with the appropriate contact person.

Process control room built for PCK refinery

PCK Raffinerie GmbH in Schwedt/Oder is one of the top companies in Brandenburg and the most important company in the Uckermark. Around 12 million tonnes of crude oil are processed into petroleum and petrochemical products in Schwedt every year. The main products are diesel, petrol, kerosene, liquefied petroleum gas, heating oils and bitumen. PCK was one of the first refineries in Germany to use biofuels and is itself a major producer of high-quality biofuel components.

Chief Divisional Engineer for Processing (PCK) / Divisional Engineer for Maintenance Service and Project Coordinator (PCK) / Managing Director (JST)

Process control room constructed as the heart of the MVA - waste recovery plant

All operating and emissions data are collected by them, they check that the limit values are never exceeded, thus guaranteeing the highest safety standards: The operators in the new control room of Müllverwertungsanlage Bonn GmbH (MVA), a subsidiary of Stadtwerke Bonn, are responsible for monitoring all data and functions at the core of the plant. This important task is supported by products from Jungmann Systemtechnik – JST.

Plant Manager of MVA Bonn

Process control room completely constructed

The monitoring of around 2,000 computer systems is the focus of the employees at Audi’s so-called “MMS” control room in Ingolstadt. MMS – that stands for Manufacturing Management System. This involves continuous testing of all the steps required to produce the various models. The new control room was equipped by the control room specialists from Jungmann Systemtechnik.

Head of Maintenance Processes and Systems Engineering / Control Center Coordination / Project Manager

Documents for download

Was möchten Sie als Nächstes tun?

- das kostenfreie Praxisbuch der Kontrollräume anfordern

- einen Rückruf für eine unverbindliche Beratung

- den Kontrollraum-Simulator in Buxtehude besuchen

- eine digitale 360°-Tour in einem Kontrollraum erleben

- mehr über Kontrollräume auf dem ko:mon Kongress erfahren

We are happy to answer your questions on the construction of the process control room

0800-777 8 666You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information