Expand your measuring station with JST – Your investment will pay off quickly

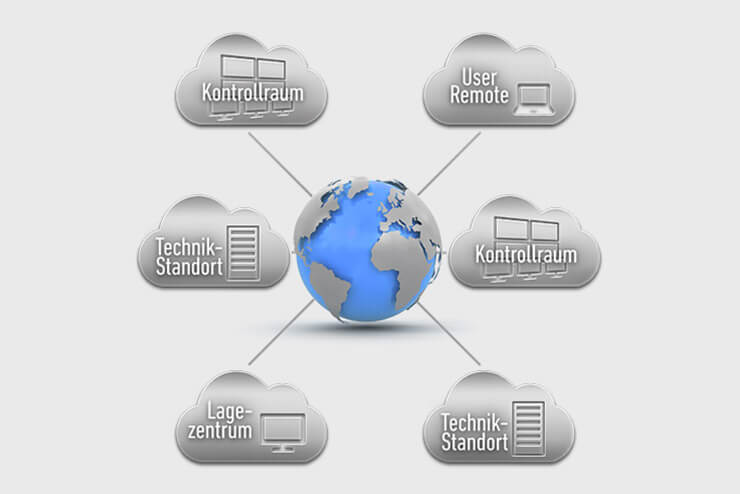

Regardless of whether you want to expand individual areas of your measuring station or are considering a complete reconstruction: JST’s planning know-how for measuring station expansion is state-of-the-art. You decide whether we should make comprehensive changes or take action in subareas of the existing measuring station.

JST is known throughout Germany for its carefully thought-out solutions for expanding measuring station. We skilfully assemble the optimal components for your needs. Our ergonomic control room furniture provides support for the operator during their shift. At the same time, we focus on creating an appealing visual design: We are happy to build our surrounding furniture to match your corporate design.

OFFER EXPAND MEASURING STATION

-

We will coordinate our plans for expanding the measuring station on an individual basis.

-

We will make your measuring station fit for the future.

-

The expanded measuring station takes ergonomics and comfort into account.

-

We are happy to adapt new surrounding furniture to your CI.

-

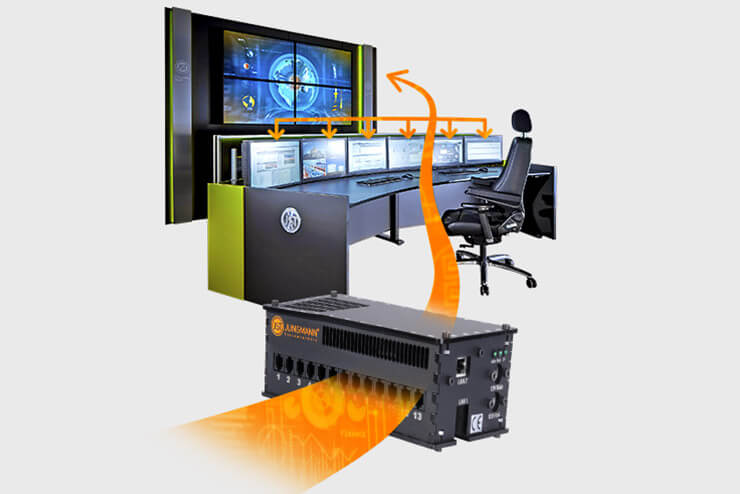

No changes to the hardware/software of your systems necessary!

Practical examples: Measuring station expansion

Industrial measuring stations must be able to meet the highest demands. Anyone working in 24/7 continuous operation knows about the demanding tasks that employees face around the clock. Here it is not only important to meet the special safety requirements with an optimally designed measuring station, but to guarantee them 100%. No compromises. We will analyse, plan and implement the appropriate overall concept of reliable solutions down to the smallest detail. This is exactly what our passion is! Take a look at our reference projects to get an idea of what we do for measuring stations across a wide range of industries.

We will be happy to put you in touch with the appropriate contact person.

Expanded measuring station for PCK refinery

PCK Raffinerie GmbH in Schwedt/Oder is one of the top companies in Brandenburg and the most important company in the Uckermark. Around 12 million tonnes of crude oil are processed into petroleum and petrochemical products in Schwedt every year. The main products are diesel, petrol, kerosene, liquefied petroleum gas, heating oils and bitumen. PCK was one of the first refineries in Germany to use biofuels and is itself a major producer of high-quality biofuel components.

Chief Divisional Engineer for Processing (PCK) / Divisional Engineer for Maintenance Service and Project Coordinator (PCK) / Managing Director (JST)

Chemical control room: highest availability

With 2,200 employees in four business divisions, INEOS in Cologne is one of the largest locations of the INEOS Group. These business units also include INEOS Oxide, Europe’s largest producer of ethylene glycol. The production of this basic chemical as a starting material for various end products – from antifreeze to polyester fibers – is monitored in a modern control room that Jungmann Systemtechnik (JST) designed and installed for the chemical company.

Consultant (JST) / Technician PLT (INEOS) / Technician PLT (INEOS) / Production Engineer PLT (INEOS)

BASF control room paves the way to sustainable value creation

Using renewable energies for production on an industrial scale is one of the declared goals of BASF Schwarzheide GmbH. With a new Jungmann control room for monitoring and controlling the gas and steam turbine power plant at the Schwarzheide site, the necessary preconditions for this have been created. The state-of-the-art control room serves as the basis for a more flexible operating regime and complete monitoring of processes. It was not only the effortless handling and the comprehensive operating options of the MultiConsoling® technology that convinced the project managers. Ergonomics and design also played a decisive role.

E&I Engineering BASF SE // Consultant JST

Documents for download

Was möchten Sie als Nächstes tun?

- das kostenfreie Praxisbuch der Kontrollräume anfordern

- einen Rückruf für eine unverbindliche Beratung

- den Kontrollraum-Simulator in Buxtehude besuchen

- eine digitale 360°-Tour in einem Kontrollraum erleben

- mehr über Kontrollräume auf dem ko:mon Kongress erfahren

We are happy to answer your questions on the expansion of measuring stations

0800-777 8 666You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information