Renewable energy: Modern control room monitors processes

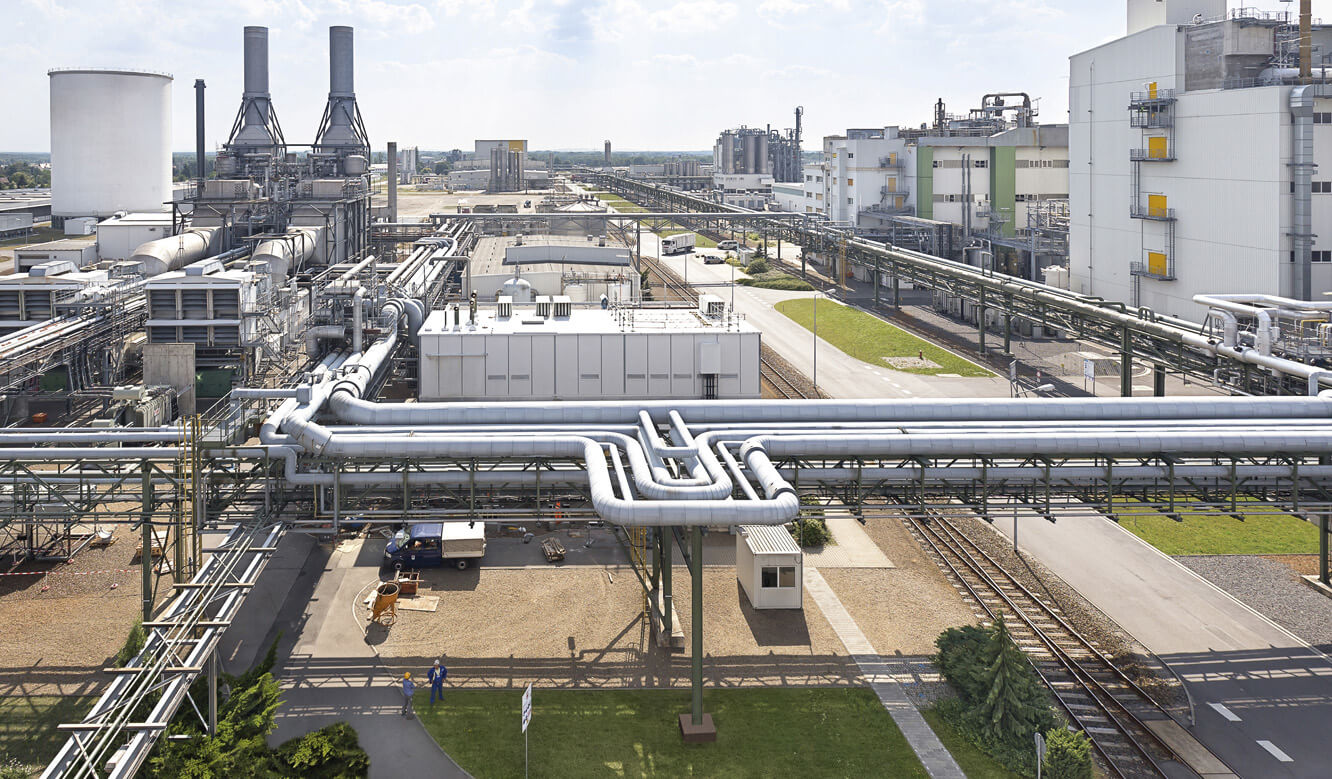

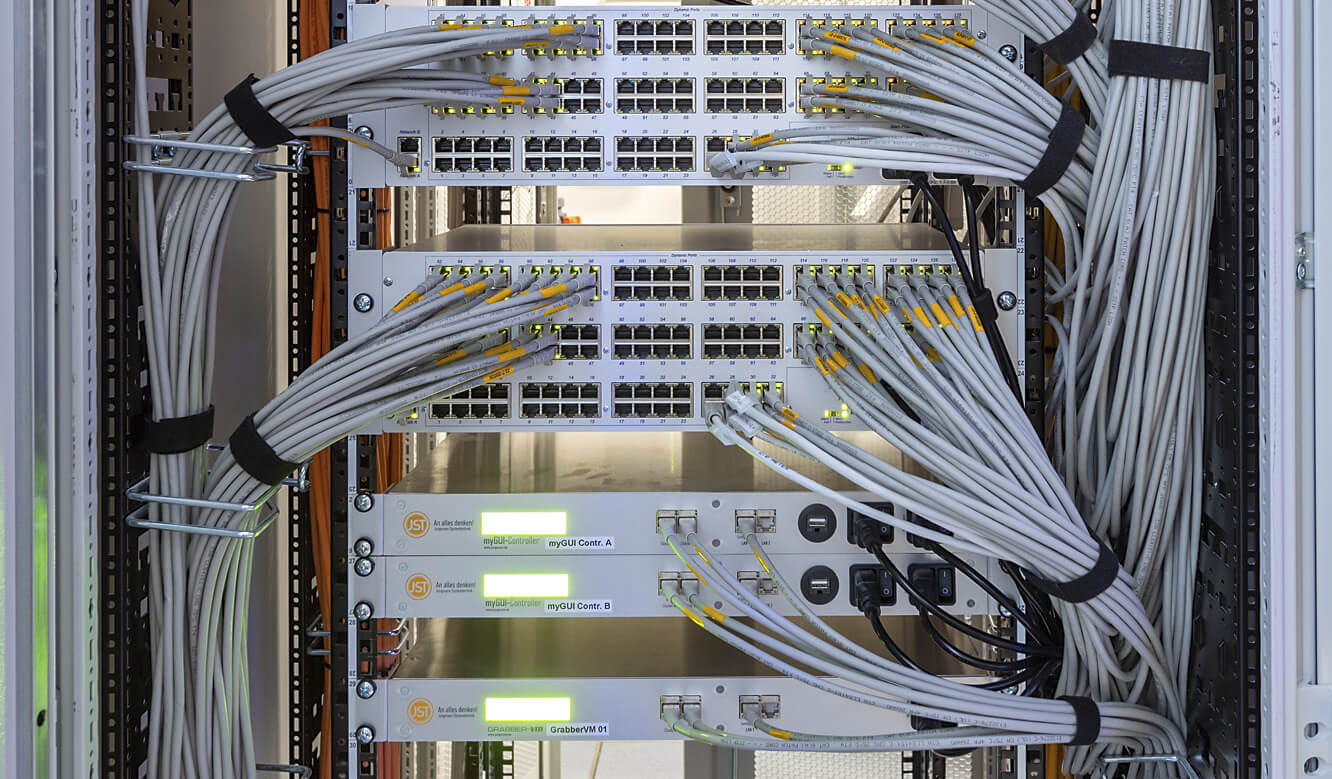

They set the course for sustainable growth early on and were thus able to create a robust basis for a future-proof site against the backdrop of the current energy crisis. In 2019, BASF already invested 73 million euros in the modernization of the combined-cycle gas turbine (CCGT) power plant at the Schwarzheide site in Lusatia. A state-of-the-art control room, which was implemented by BASF in cooperation with the control room experts from JST – Jungmann Systemtechnik®, is responsible for monitoring and controlling this plant. The declared aim of the project is to enable the use of renewable energies as the basis for sustainable value creation.

“As a medium-sized, self-supplied industrial site, we want to take new, innovative paths when it comes to energy,” says Jürgen Fuchs, Managing Director of BASF Schwarzheide GmbH, on the background to the CCGT modernization. In order to use renewable energies on an industrial scale for production in the future, a more flexible operating regime for the company’s own power plant and seamless monitoring of the processes are required. This is precisely where the new control room comes into play.

Recommendation of colleagues was best reference

Whether pressure or temperature, filling level or valve position – the operators in the CCGT control room not only use state-of-the-art technology for their tasks, but also ergonomic furniture. Vitali Goldnik, responsible for E&I Engineering at BASF’s Brandenburg site, remembers the first steps on the way to the new control room well: “We had the best reference you can imagine. Our colleagues at the Ludwigshafen site had already worked successfully with the Jungmann team. In addition to the recommendations of our colleagues, we even had a JST sample control station at our disposal in Ludwigshafen. We were able to test all systems there and quickly saw the benefits of the existing solutions.”

Flexibility and performance "a great experience"

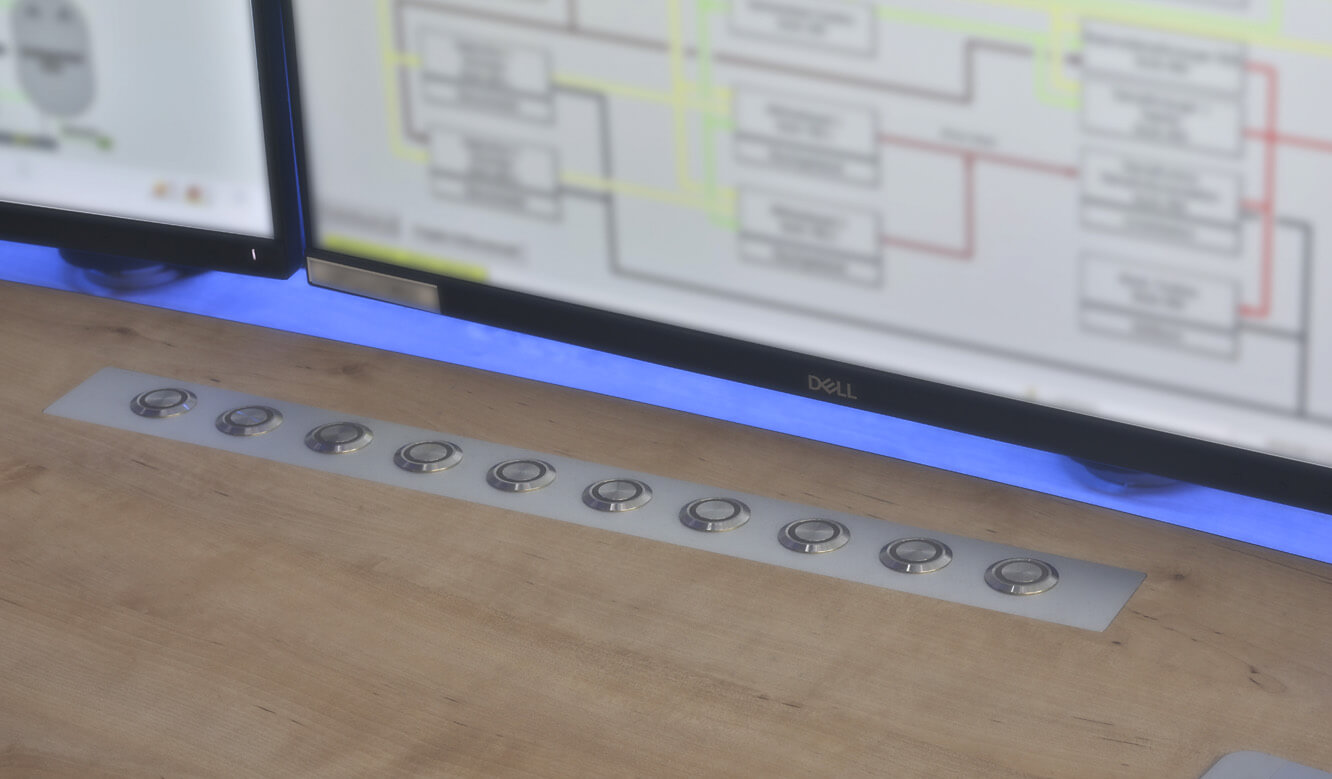

The project manager was convinced by the effortless handling and the comprehensive operating options with MultiConsoling® technology. Advantages of control room operation with MultiConsoling®: Any source can be switched to any desired screen. Only one mouse and keyboard are required for all applications. And all this with intuitive operation using the myGUI® interface. “The high flexibility, the reliable performance, no more annoying chair moving – that was already a great experience,” reports Vitali Goldnik.

Interactive experience in the new control room: Zoom, rotate, nighttime view and change of perspective – here you can experience control room concepts in interactive 360 degree visualisations! How does the new control room look? How can the operator consoles be optimally positioned? How big should the monitor wall be? With professional 3D studies and virtual tours – here at BASF in Schwarzheide – these and many other questions can be answered at an early stage of the project. Light influences, colours, spatial conditions – there are almost no limits to the design possibilities. Go on a three-dimensional journey of discovery now!

Technically, ergonomically and visually convincing

But in addition to intelligent technology, the expert for process control technology had another demand on the JST control room professionals. The measuring station for the power plant not only had to be state of the art in terms of technology, but the furniture also played a decisive role. Functional and visually convincing solutions for a conference room, for the reception area and other special furniture were required. Vitali Goldnik: “When comparing with other equipment suppliers, it was clear to see that JST has great experience in terms of ergonomics and design.” Thus, the Jungmann team was able to convince with individual custom-made products from its furniture manufacture and prevail over the competition.

A "very good" for the cooperation with JST

A decision that the project manager would make again at any time when looking at the new control room. Planning including 3D visualizations, consulting on smart control room concepts with the OPAL acoustic ceiling sail, the latest large-screen technology or proactive alarming options – “this was really a very good cooperation,” Vitali Goldnik sums up.

Control room before and after renovation

Our references today (selection)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)