Control room automation: How smart technology tools support alarm handling and processes

Automated control room management is becoming increasingly important as tasks in the control station become more complex. Modern control rooms rely on intuitive operating concepts when it comes to alarm management, process automation and KVM control in the monitoring center. The solution: ControlRoom Automation from JST. Innovative components make it possible to connect external technology, trigger internal actions or activate preconfigured scenarios. CommandButtons, CommandButton Interface, IOBox 5/5 and CommandPad stand for simple, secure and highly flexible operation.

Instant reaction to recurring events

JST’s ControlRoom Automation components automate time-consuming routine tasks. At the same time, however, the operator retains complete control over all systems. Recurring tasks are executed at the touch of a button or, optionally, performed fully automatically. JST automation components communicate with connected technology and linked software programs. In this way, switching signals are recorded, monitored and processed without operator intervention. Depending on the requirements on site, the input and output signals can be linked to individually defined actions.

Operators use the CommandButtons or the CommandPad touch interface to start individually predefined processes – from switching important sources to fully automated alarm activation on the video wall.

The IO Box 5/5 records input signals (potential-free contacts from building management systems or process control) and forwards them to the myGUI®. There, predefined scenarios are automatically started.

Whether signals are incoming (input) or outgoing (relay control): with the IO Box 5/5, almost all switching signals can be monitored, evaluated and directly linked to the desired software actions or hardware components.

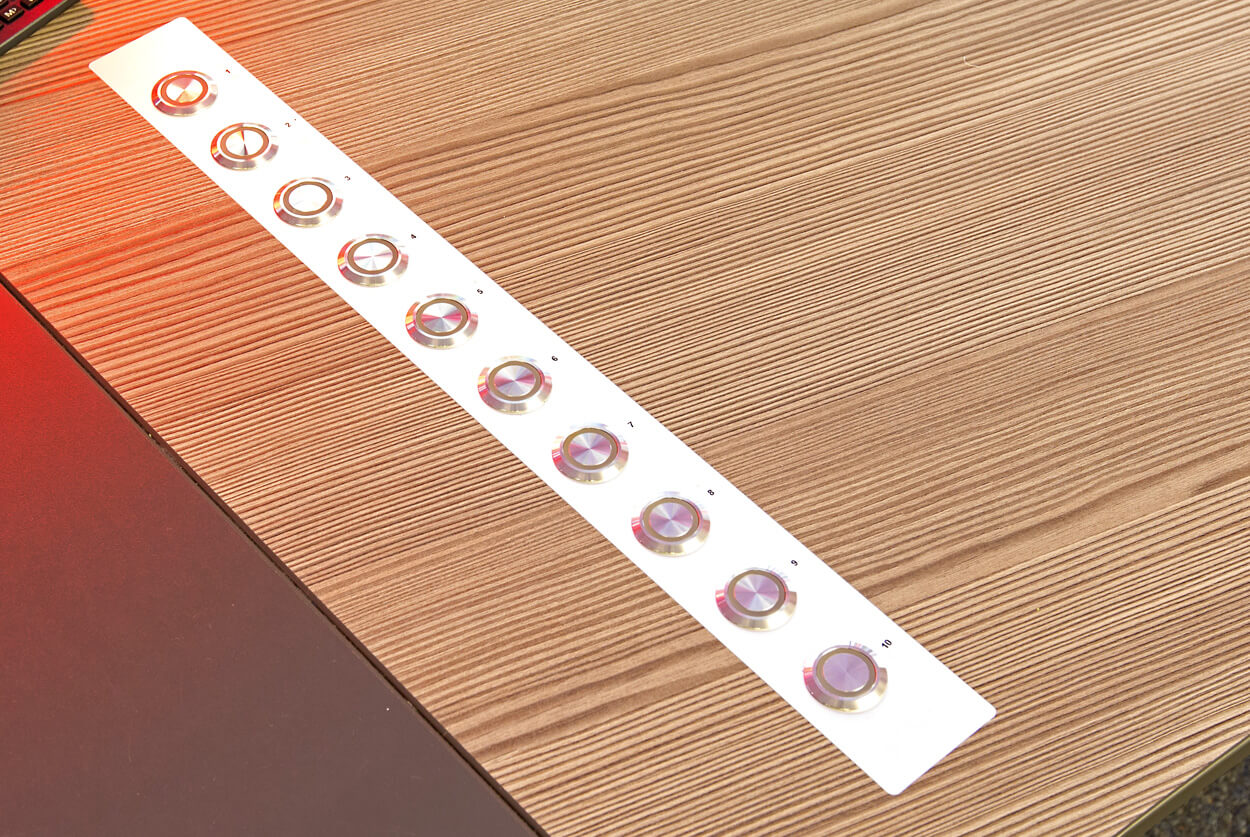

Confirm alarm! Open door! Turn on lights! The command buttons in the surface of the Stratos operator consoles make it possible to operate control room technology at the touch of a button. Employees have a quick, haptic way of triggering the desired actions. The buttons can be freely and individually linked to the selected commands.

Powerful arguments for control center automation with innovative solutions from JST

Work simplification: Operators receive reliable support.

Speed: Alarms are activated within seconds.

Security: No more prioritised alerts will be lost.

Teamwork: System display for all operators on the video wall.

Flexibility: All potential-free contacts are processed.

Strong duo: CommandButtons and CommandButton Interface

Robust hardware buttons for direct and secure quick access to prioritised systems. Each button press is forwarded from the CommandButton interface to the myGUI® operating software. Ideal for fast, haptic control; for example, switching sources or starting predefined myActions.

Typical application: An operator presses the “Alarm Escalation” command button to simultaneously switch the large screen to a critical camera image and trigger an audible alarm.

Technical details: Each button can be freely assigned functions, illuminated in colour (status display) and organised into groups. Signals are transmitted via network protocols – quickly, reliably and configurably.

Fast and secure with one touch

Fast and secure with one touch

The IOBox 5/5 – your bridge to external technology

If external signals or relays need to be switched in addition to the software actions within the myGUI® cosmos, the IOBox comes in. Alarm sounds can be activated, lights can be controlled, or feedback from the building or process control technology can be received.

Typical application: A smoke detector sends an alarm signal to the IOBox via a potential-free contact. The signal is sent to the myGUI®, and the defined scenario starts automatically; for example, alarm visualisation, warning sound and display on all operator workstations.

Technical details: The IOBox offers five digital inputs and five potential-free relay outputs. It operates redundantly and allows flexible signal interconnection in both directions (input and output).

All dry contacts under control?

All dry contacts under control?

JST CommandPad®: full control via finger touch

The CommandPad brings the user interface of the myGUI® platform to a compact touch panel. Whether switching sources, starting scenarios or controlling alarms: with a tap of your finger, you can control all functions centrally, intuitively and efficiently.

Typical application: With just one touch, the operator activates a predefined “night mode” scenario: monitors dim, alarm lights switch to standby mode, and audio levels are adjusted.

Technical details: The JST CommandPad® is based on a high-quality touch display and is available as either an integrated or mobile version. It can be connected via LAN or WLAN and allows convenient control of all myGUI® functions without additional peripheral devices.

The secure way to greater convenience

The secure way to greater convenience

KVM – the key to automated control room management

The basis for automated control room management is a KVM system (KVM = keyboard, video, mouse), which offers efficient workflows and maximum security with just one control unit. Whether as an IP-based variant with JST MultiStreaming® or the hardware alternative with MultiConsoling®, KVM infrastructures deliver maximum flexibility in system operation, fast source switching, intuitive visualisation and continuous control room availability. Customers benefit even with growing requirements and complex system landscapes.

With the myGUI® software, KVM technology is also complemented by a clear user interface. The interface of the operating platform reflects the operator’s workplace as an individual 3D graphic, which is characterised by its intuitive operation.

Open the gateway to automation!

Open the gateway to automation!

JST projects prove: automation in the control room provides convenience and security

Automation in control rooms reduces the workload on operators and lowers the risk of human error. Escalation chains and the automatic activation of predefined scenarios at the touch of a button minimise the pressure on the control room team. Thanks to the innovative components of JST’s ControlRoom Automation, hundreds of monitoring centers are already benefiting from modern automation solutions in a wide range of applications. Take a look at JST projects in which routines and recurring workflows are executed at the touch of a button.

Your workshop experience: Try out our automation solutions!

Control room concepts that simplify processes in the control center and make them safer – that’s what we at JST are all about. But which solutions are the best? How convenient are they to use in practice? Visitors to the control room simulator can try out our systems live on site. In this unique room of the future, everything revolves around process visualisation, operating concepts and ergonomics. Take advantage of the free workshop in the control center showroom as a practical planning aid and lay the foundation for future-proof investment decisions – either live or in a virtual meeting.

The control station you can touch – free live event in JST’s control room simulator.

We offer our customers unique products and solutions for control rooms. An exclusive benefit that only JST can provide.

We have been working in the business for more than 30 years. We would be happy to bring our many years of know-how to your project.

This means that you benefit from our extensive experience and smooth project realisation processes. Because JST keeps everything in mind!

Our experts are among the best. They have been designing control rooms for years. Our team enjoys working together – for you!

Intelligent tools for reliable process control

Network-based KVM technology: smart and secure with JST MultiStreaming®

Efficiency, productivity, security – that’s what JST MultiStreaming® stands for. Connect all sources conveniently and flexibly via the network using IP streaming. Even remote access to worldwide target locations is possible – stable, in great quality!

Video wall, workstation and infrastructure under control with the myGUI® platform

The intuitive myGUI® user interface in the 3D layout of your control room offers maximum ease of use for controlling your systems. With just one click you can operate workstations, monitor walls and infrastructure – reliably, even in stressful situations!

MultiConsoling® – the high-availability command center for your control room

MultiConsoling® is the high-availability control center for connecting all of the signals from your systems to the monitors at the operator’s workstation and on the monitor walls. Transmission takes place in real time and does not require any software on your computers.

The most frequently asked questions about automation in the control room

Below you will find answers to the most frequently asked questions we receive about ControlRoom Automation. If you cannot find the information you are looking for on the subject of “automation”, simply contact us.