Command center for production control integrates logistics, manufacturing and quality management – for maximum efficiency in the automotive plant

In the automobile factory, all steps mesh exactly like gear wheels. Deviations or even failures result in enormous costs. In the worst case, the entire production is forced to a standstill.

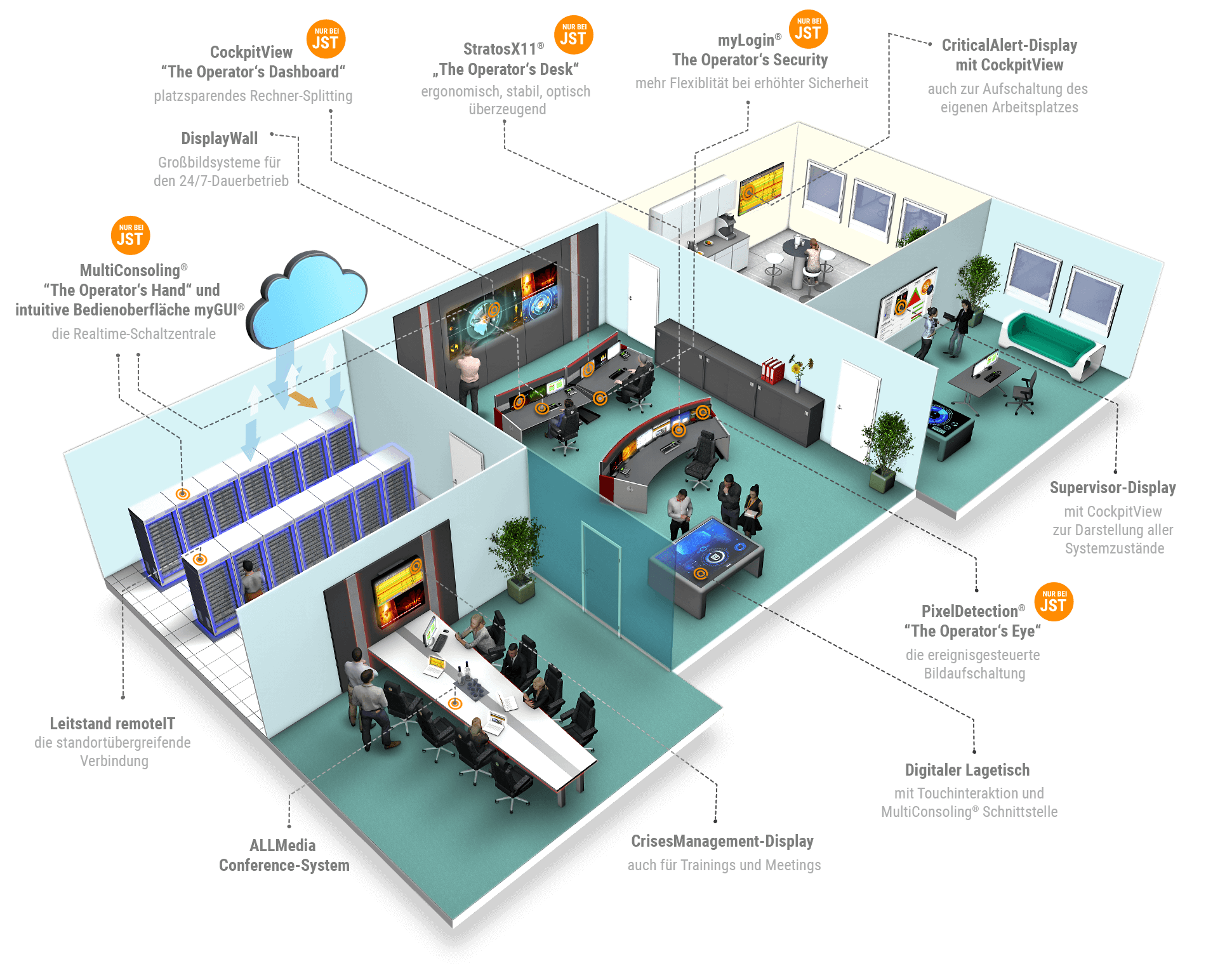

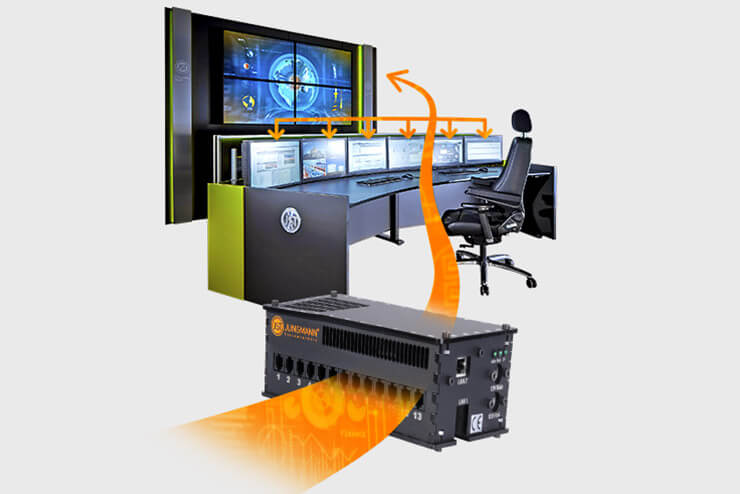

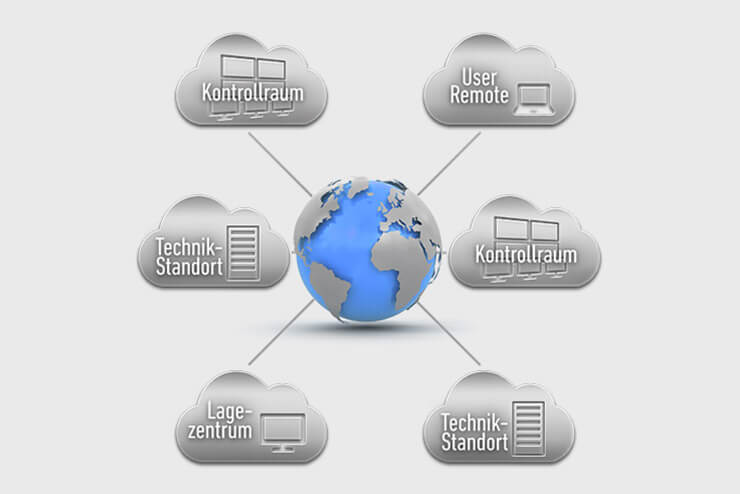

With innovative components, JST delivers turnkey solutions for secure production control – from planning to service level agreements (SLA). Ergonomic control room furniture and proactive monitor walls make the command center the strategic hub of production. For real-time monitoring of logistics and manufacturing as well as quality control, KVM systems with the intuitive myGUI® user interface set new standards in flexibility.

-

Individual analysis of the requirements

-

All stations under control at all times

-

Shortened reaction times for fast action

-

Perfect visualization of all processes

-

Handmade control room furniture from Germany

-

Spatial planning including 3D representation

Chosen by leading companies and institutions

Practical examples: These control centers are all about production control

The job in the central control center of a vehicle manufacturer is not for the faint of heart. Several hundred individual stations can be monitored closely. If, for example, a supplier has a problem with a component, fast and clever action by the employees is the top priority. To achieve this, the virtual IT reliably supports the control in 24/7 operation. JST has three decades of accumulated expertise in the design of control centers for production control, logistics, vehicle manufacturing and quality monitoring.

We will be happy to put you in touch with the respective contact person.

AUDI AG re-equips control room for central production monitoring

Stylish limousines, sporty allrounders and sleek coupes – more than 2,500 cars roll off the production line at the Audi plant in Ingolstadt every day, in 2013 more than 570,000 cars were produced here. To ensure that production never comes to a standstill, more than 30 employees in three shifts ensure that everything runs smoothly. Jungmann Systemtechnik – JST – has created the ideal conditions for this.

Responsible for IT scopes in the department and planning of the project / former head of vehicle control

Digital upgrade for the "brain" at Volkswagen

Within the Volkswagen factory it is called “the brain of the factory”: the FIS control center. FIS – that stands for vehicle information and control system. This is exactly what the Wolfsburg control center is all about. The entire vehicle production process is monitored and controlled from here; from the receipt of orders for the plant to the entry into the assembly lines. It is easy to understand that technology and ergonomics must meet the highest standards. With the support of the control room specialists from JST – Jungmann Systemtechnik a comprehensive update has now been realized.

Head of Operational Vehicle Control Center at Volkswagen in Wolfsburg

Production control center completely new equipped

The monitoring of around 2,000 computer systems is the focus of the employees at Audi’s so-called “MMS” control center in Ingolstadt. MMS – stands for Manufacturing Management System. This involves the continuous monitoring of all steps necessary for production control in the vehicle manufacturing process for the various models. The new control center was equipped by the control room specialists from Jungmann Systemtechnik.

Head of maintenance processes and systems engineering / control center coordination / project manager

Was möchten Sie als Nächstes tun?

FAQ

How can ergonomically optimized and standardized workplaces be created in the command center for production control?

Unfortunately, control rooms in automotive plants often still show a disorderly overall picture. Countless monitors, keyboards and mice rule the chaos on the operators’ desks and demand unnecessarily much precious time and concentration.

When monitoring and control monitors overlay the workstations and are no longer within the operator’s immediate field of vision, he quickly loses the overview. We bring order to the system! The operator can now switch on various computers, cameras and signals at any point according to the situation.

When JST redesigns and modernizes a control center for vehicle production, old problems are cleverly eliminated. An ergonomically optimized workplace has ideally three screens, a keyboard and a mouse. The employees are supported by intelligent Profi-tools. This allows each individual to concentrate well throughout the shift.

The employees carry a great responsibility. They control the process from the receipt of orders for the plant to the entry into the assemblies. The aim is to create optimized sequences for the entire factory. In parallel, a number of logistical processes, such as picking or material calls, are initiated. This is why the control center is manned around the clock. Materials and components are always in the right place at the right time. Essential production data is directly available with one click and the shifts of the required specialists are precisely timed.

We need a big screen for our control center. What solution does JST offer?

Here we offer our monitor walls with seamless 24/7 LC displays and alarm function.

The JST DisplayWalls are the eye-catcher in every control room.

They are made up of several LCDs or rear-projection cubes.

The result is a large and coherent picture.

The screens have a narrow frame, but the interruption is hardly visible.

Monitor walls are active with the appropriate software even without the intervention of the operator.

They can be controlled by the PixelDetection® from JST, providing the tremendous benefit of providing all employees with the right information at the right time on an event-driven basis.

This indispensable Profi-Tool contributes significantly to the recognition of important alarms and the reduction of response times in the control room.

Our PixelDetection® software reacts reliably to a previously defined event such as an incoming alarm.

The event can be switched on automatically and operated in real time.

The entire team on site immediately has the same level of knowledge at a glance.

This is what we call “Teamview”.

What are the advantages of JST Displaywalls?

- Ideal representation: On the large monitor surface, different but currently relevant alarms are quickly, clearly and perfectly visible from any angle.

- Faster with Teamview: The whole team receives all important information at the same moment.

With this expansion of their own workstation desktop, the team can react faster, eliminate interference and act efficiently. - Clear structure: Monitoring and control is made possible by combining various system, plant and hazard states.

The operator has everything perfectly in view at all times. - Event controlled alarm: No alarm goes undetected anymore.

The most important alarms appear at the necessary time, in the ideal place, in the perfect size and immediately visible to everyone. - Design and AmbientLight: As an option, the JST display walls can be extended by a high-quality cladding with integrated AmbientLight.

The AmbientLight can be given the function of informing the entire team via light impulse in particularly critical situations or alarms. - Durability at 24/7: Our display walls are explicitly designed for 24/7 operation.

You have questions about the control room for production control? We are glad to help!

+49 40237681-100