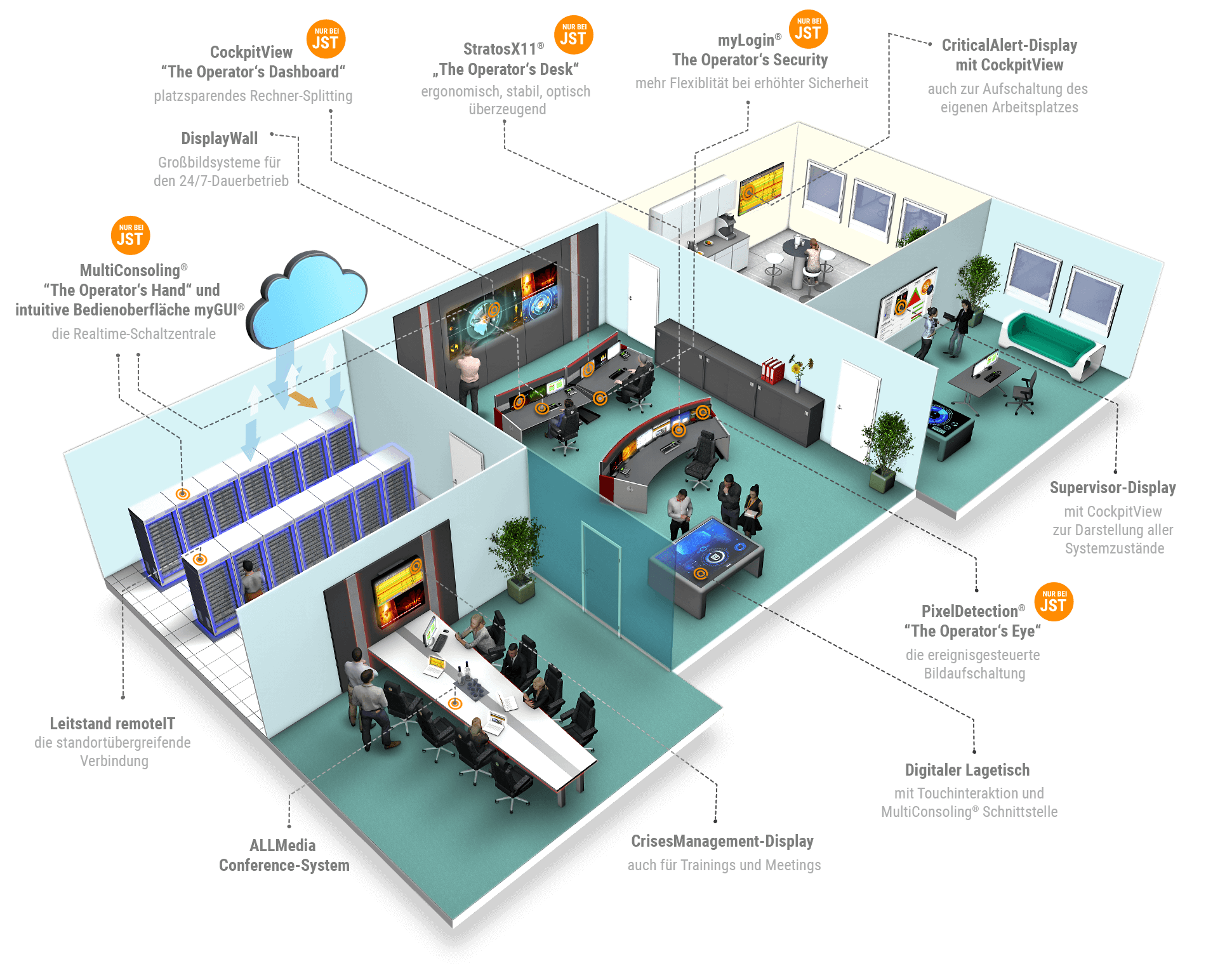

Manufacturing control room: technology, ergonomics and appearance

If you want to take your production control station to the next level, you’ve come to the right place at JST. With intelligent and field-tested solutions for 24/7 operation, you will not only have the production control station for manufacturing perfectly under control. But it will also reduce the workload on your employees and the pleasant working atmosphere will give them new motivation.

Whether you are looking for ergonomic control room furniture or new monitor walls, are planning a new production control station for your production facility or want to modernise an existing one. We provide comprehensive analysis, planning and advice according to your needs.

-

Individual analysis of the requirements

-

All stations under control at all times

-

Short reaction times = fast action

-

Optimal visualisation of all processes

-

Control room furniture made in Germany

-

Monitor walls for 24/7 operation

Chosen by leading companies and institutions

Practical examples: Production control station for manufacturing

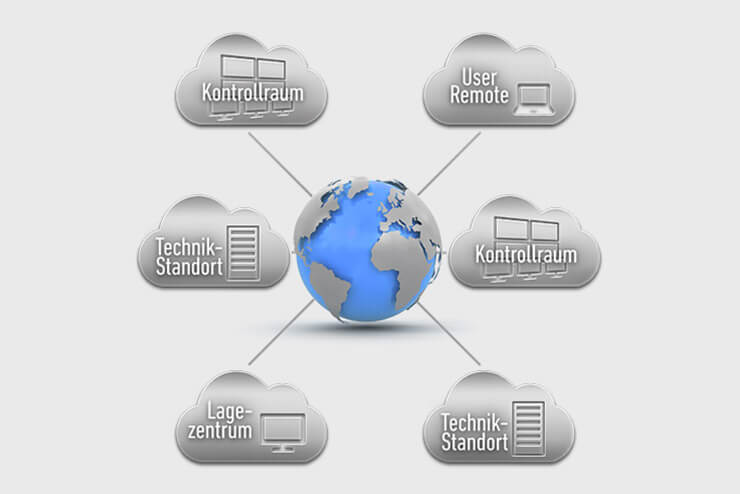

JST Systemtechnik has a great wealth of experience in the planning and implementation of production control systems for different manufacturing and industries. Our know-how also includes the consolidation and centralisation of several control rooms into one central office. Our projects often end up becoming the showpiece of large corporations. We are particularly proud of this. Learn more about it in our exciting practical examples!

We will be happy to put you in touch with the appropriate contact person.

Europe's most state-of-the-art refinery measuring station successfully goes into operation

Every year, PCK Raffinerie GmbH processes around 12 million tonnes of crude oil into petroleum and petrochemical products. All production facilities were monitored and controlled via a central measuring station furnishing from 1993, which had become too small and unmanageable over the years. As a result, those responsible decided to replace it with an ultra-modern, approximately 1,000 m² control room. Jungmann Systemtechnik GmbH & Co. KG (JST) was entrusted with the interior design and technical equipment: In addition to six control stations with a total of 25 operator stations and 78 monitors, the control room experts also installed large display walls with 100 displays, which are used proactively to control the systems. A special MultiConsoling concept reduces monitors and reaction times, creates an overview and enables particularly efficient work.

Chief Divisional Engineer for Processing (PCK) / Divisional Engineer for Maintenance Service and Project Coordinator (PCK) / Managing Director (JST)

Planning and installation of the new control room for the cement plant

It was a long way from the old mosaic picture technique to the presentation of all processes on the modern large display wall. With the support of the experts from Jungmann Systemtechnik, the Spenner Zement company was able to open its doors to technical progress in control technology. Four distributed operating and control stations were combined into a modern control room at the company headquarters in Erwitte, North Rhine-Westphalia.

Production Manager

Process control room constructed as the heart of the MVA - waste recovery plant

All operating and emissions data are collected by them, they check that the limit values are never exceeded, thus guaranteeing the highest safety standards: The operators in the new control room of Müllverwertungsanlage Bonn GmbH (MVA), a subsidiary of Stadtwerke Bonn, are responsible for monitoring all data and functions at the core of the plant. This important task is supported by products from Jungmann Systemtechnik – JST.

Plant Manager of MVA Bonn

Was möchten Sie als Nächstes tun?

FAQ

We would like a new large display screen in our production control station for 24/7 use. What is the current standard in the industry?

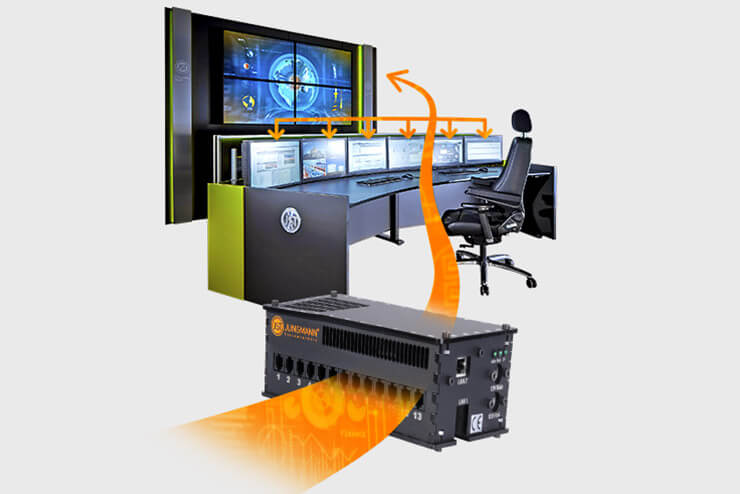

Our monitor walls with seamless 24/7 LCD displays and an alarm function meet the most advanced standards in our industry. JST-DisplayWalls are the focal point in every production control station. They are composed of several LCDs or rear-projection Cubes and can be combined to produce a large, connected image as required.

Using the appropriate software and professional tools, JST monitor walls are always in motion, even without operator intervention, and reliably display the desired information. PixelDetection® software from JST is one such tool. This ensures that all employees receive the right event-driven information at the right time. In an emergency, this helps to identify important alarms and shorten response times. We believe it to be an indispensable tool.

We are interested in JST Displaywalls in the production control station. What are the highlights?

- Perfect display: All currently relevant alarms are quickly, clearly and perfectly visible on the large monitor surface. And this from every angle.

- Clear structure: Everything perfectly in view, because the control system enables the combination of different system, plant and danger states.

- Alarm in sight: The most important alarms appear at the necessary time, in the ideal place and immediately visible to everyone. Every alarm gets noticed.

- Durability at 24/7: Our display walls are explicitly designed for 24/7 operation.

- Faster thanks to Teamview: The entire team receives all important information at the same moment. With this extension, the team can react faster, intervene and take action.

In general, how can we optimise our production control station in manufacturing?

Does this sound familiar to your production control station? Monitoring and control displays are crowded around the workstations. The desks are full of chaos from all the keyboards and mice. And the attending operator unnecessarily wastes precious time and valuable concentration in order to carry out their work sensibly under these conditions. Now JST is bringing order back into the system! Because when JST redesigns or modernises a production control station for manufacturing, old problems are consistently eliminated.

Our goal is to create an optimised workplace with a maximum of three screens, one keyboard and one mouse. We make the on-site job easier with intelligent and professional tools from our own tool forge. This allows each employee to concentrate perfectly on their tasks. We would be happy to advise you on further optimisation possibilities.

We are happy to answer your questions on the subject of production control stations for manufacturing

0800-777 8 666You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information