"Gates opened to progress"

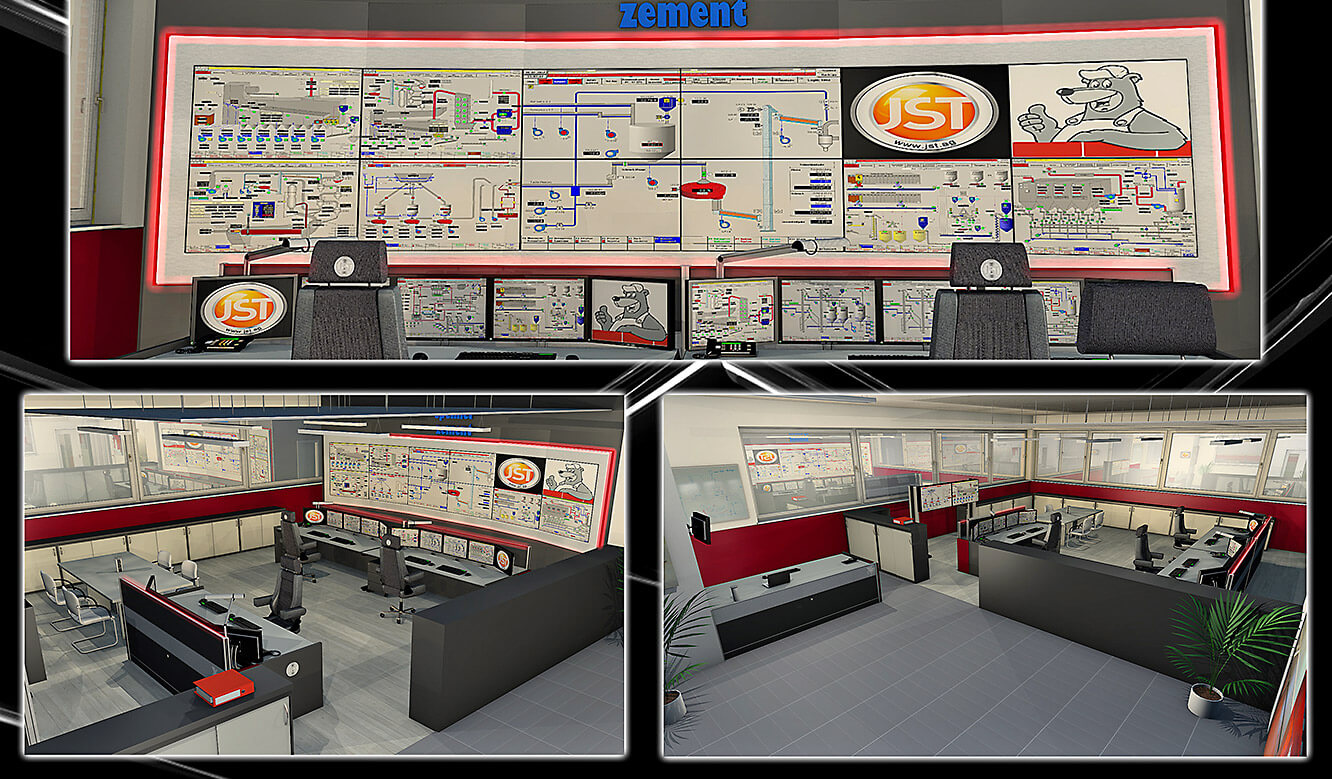

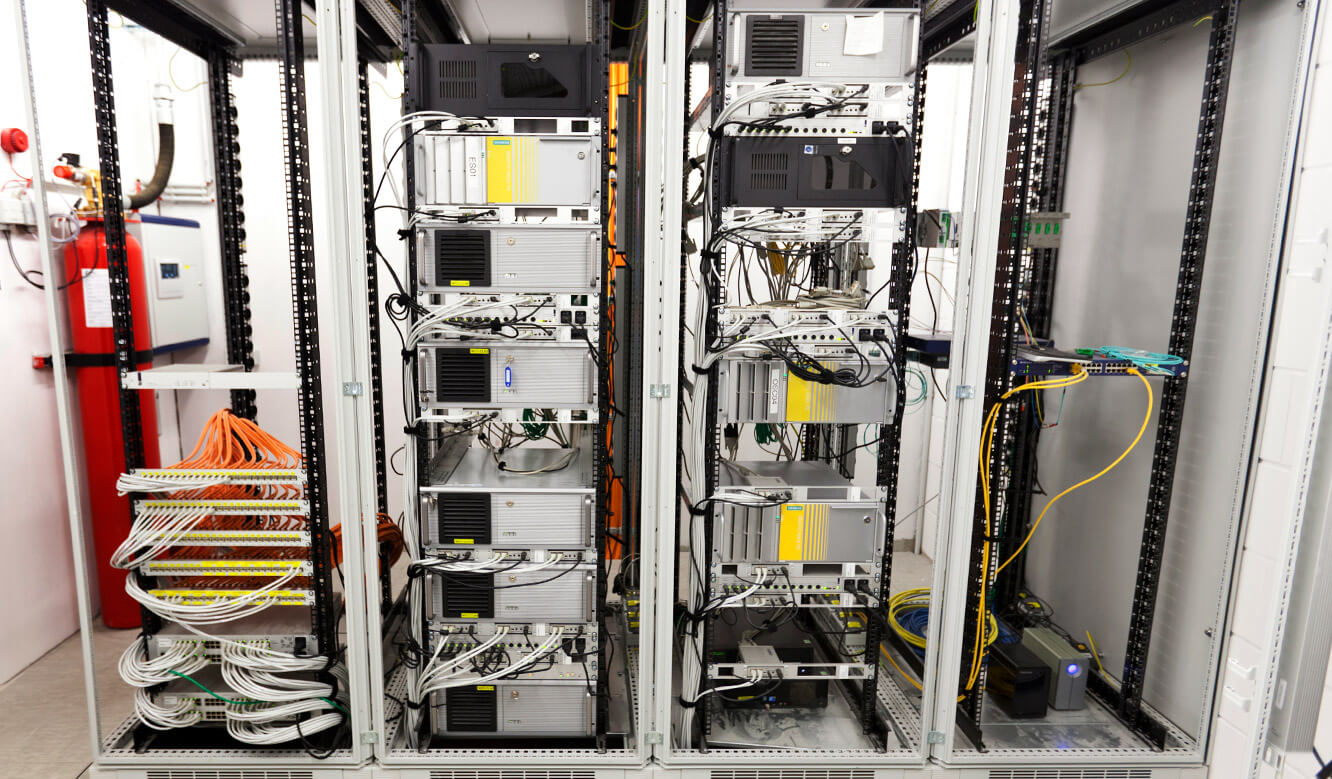

It was a long way from the old mosaic picture technique up to the representation of all processes on the modern large display wall. With the support of the experts from JST – Jungmann Systemtechnik®, Spenner GmbH has opened the door to technical progress in control technology. Four decentralised operating and control centers were combined in a modern control center at the company headquarters in Erwitte, North Rhine-Westphalia.

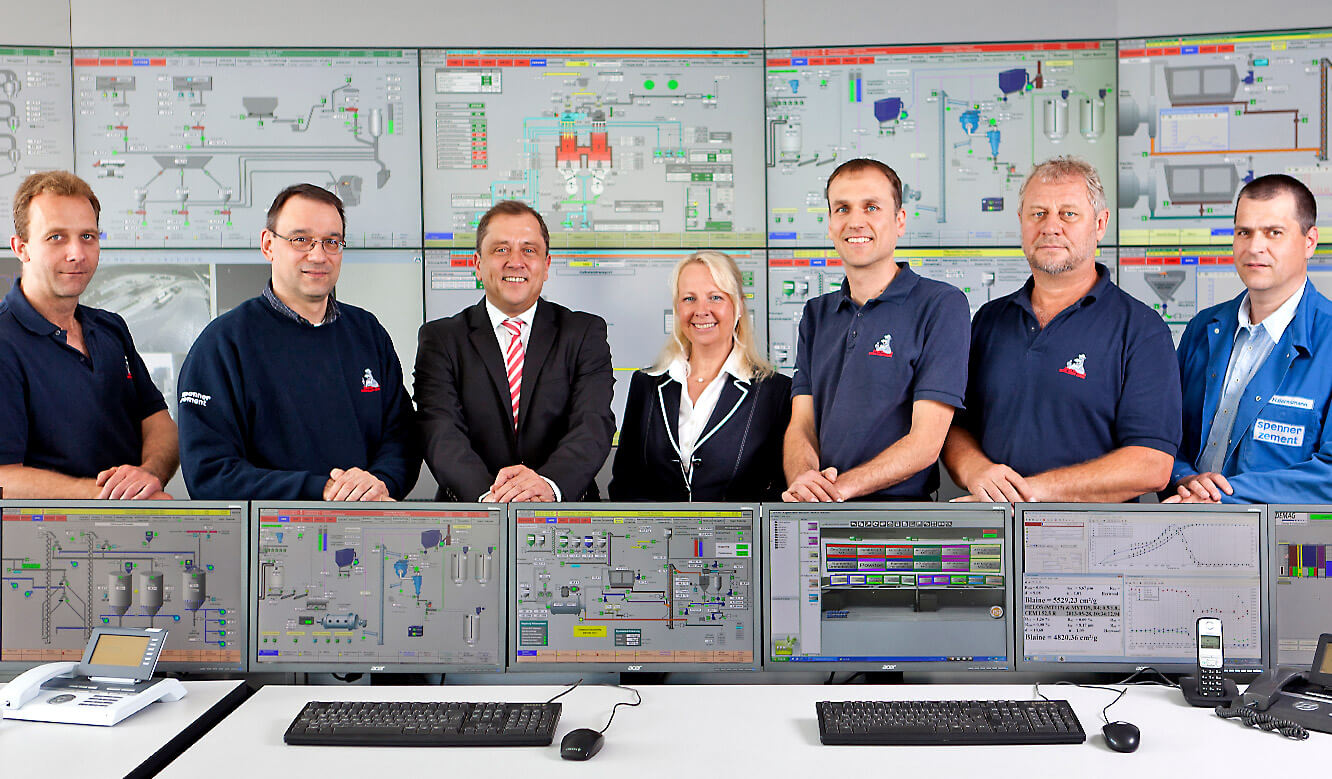

Where buttons used to be pressed and controls moved, plant operators today have to process a veritable flood of information. They are confronted with a constantly growing number of digital control technologies . A project team from Spenner has joined forces with the Jungmann specialists in order to provide the employees with a better visualisation and a faster acquisition of all relevant data. The result is a control room perfectly tailored to the company, whose technological innovations convince not only the management but also the employees.

The Spenner team became aware of Jungmann Systemtechnik via internet search engines. After an initial meeting with the JST consultants, it was already clear to Dr. Heinrich Sievers, head of production: “This could be a good fit for us. The whole package was simply coherent, and we also really liked the commitment of the Jungmann employees”.

The necessary configurations were worked out in joint project meetings and the employees at the Erwitte plant were also informed about the concept of the project via a clear 3-D planning. After all, they are the ones working with the new technology today. “The production controllers are coping well with the new plant,” says Markus Falkenstein, member of the Spenner project team and deputy production manager for clinker production. His conclusion: “The nice thing about the large display wall is that you can show the complete plant on it: from the raw mill at the beginning, through the fuels, to the rotary kiln. And all this without complicated switching.”

According to project manager Heinrich Sievers, models of all processes as well as various camera images, e.g. for monitoring conveyor belt routes, are displayed on the large display wall. “This medium is used optimally,” says Sievers, who gives the entire project the grade “completely successful and pleasing”.

About Spenner

Spenner produces and distributes cement, lime and dry building materials. In the northern half of Germany, Spenner is the largest family-owned company in its segment. The company, based in Erwitte, employs almost 250 people, about ten per cent of whom are apprentices. In addition to the site in Erwitte, two further grinding plants are operated in Berlin and Duisburg, as well as a quarry in Brilon, where the raw material for the lime products is extracted. As the parent company, Spenner GmbH & Co. KG consists of three independent companies: Spenner, Spenner Herkules and Spenner Syston. Each of the three companies covers part of the broad value chain that extends from raw rock to industrial shell construction.

Press review

Our references today (selection)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)