Remote monitoring: control room crowns "Viking" wind farm project

Around a quarter of the electricity produced in Germany is generated from wind power. And the rapid development in the regenerative energy sector continues unabated against the background of ambitious climate targets throughout Europe. One of the big players in the sector is the Spanish company Iberdrola. With the “Vikings” project, the Group has realised a wind farm in the German Baltic Sea that supplies the equivalent of 350,000 households or more than 20 percent of Mecklenburg-Vorpommern with energy. To ensure that green electricity flows without restriction thanks to remote monitoring, the team in the control room in Sassnitz relies on cooperation with JST – Jungmann Systemtechnik®.

70 wind turbines in the five-megawatt output class, an area of around 34 square kilometres and at the heart of the plant: the transformer platform. Here, all the electricity from the individual turbines is not only combined, but also converted to the required level. Nobody here can and will afford technical faults. This makes it all the more important that remote monitoring from the mainland, 70 kilometres away, is ensured by reliably stable technical installations. It is precisely this remote access, which makes the approximately one and a half hour boat trip out to the wind farm unnecessary, that is the linchpin in the control center of the “Viking Offshore Wind Farm”.

“State of the art" solution needed

For almost two years, the control room staff of Iberdrola Renovables Offshore Deutschland GmbH on the island of Rügen monitored “their” wind farm from a temporary base. But a glance at other wind energy control rooms quickly made it clear: buzzing computers under the desks, an army of keyboards and mice, each of which is connected to individual computers and repeatedly turns the activation of desired applications into a “search game” – this is not “state of the art”.

"Always bumped into Jungmann"

“There were also more convincing solutions in terms of ergonomics,” recalls Marco Schwarmann, Assistant Site Manager of the Viking Offshore Wind Farm. In his more than 20 years of experience in the wind energy sector, the expert has built up a broad network. So it was not difficult for him to combine reference visits to industry colleagues with modern control rooms. Schwarmann: “I came across Jungmann Systemtechnik again and again”. For example at JST customer “Adwen” in Bremerhaven.

The control room for the project “Vikings” before and after the reconstruction. For two years, the temporary facility served to monitor the wind farm in the Baltic Sea off Rügen.

Easily integrate new tasks

“And what I saw there really convinced me,” says the project manager. “We compared the JST concepts with the possibilities of other suppliers and found out With JST, I have the freedom to say that tomorrow I want to monitor an additional element – I can easily do that. For growing monitoring tasks, we simply add the hardware; all interfaces are already available.“

No special training necessary

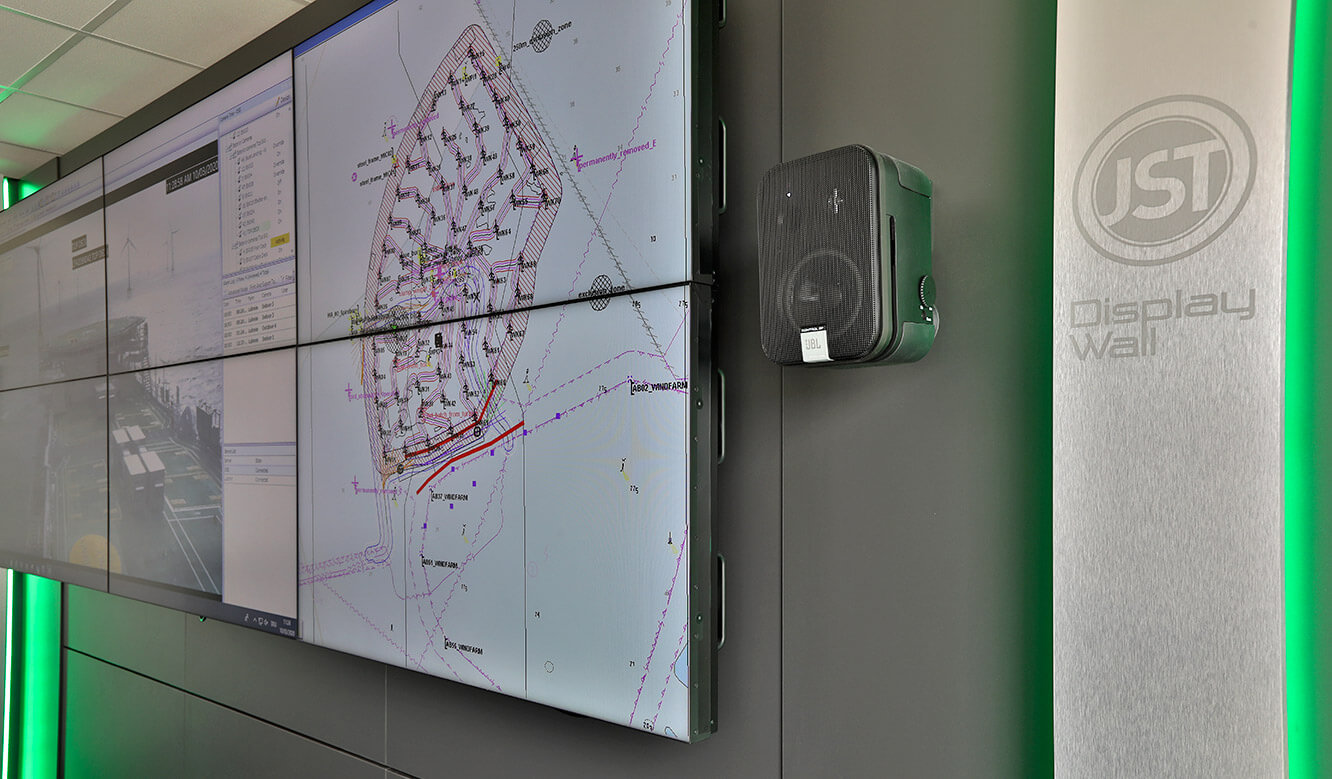

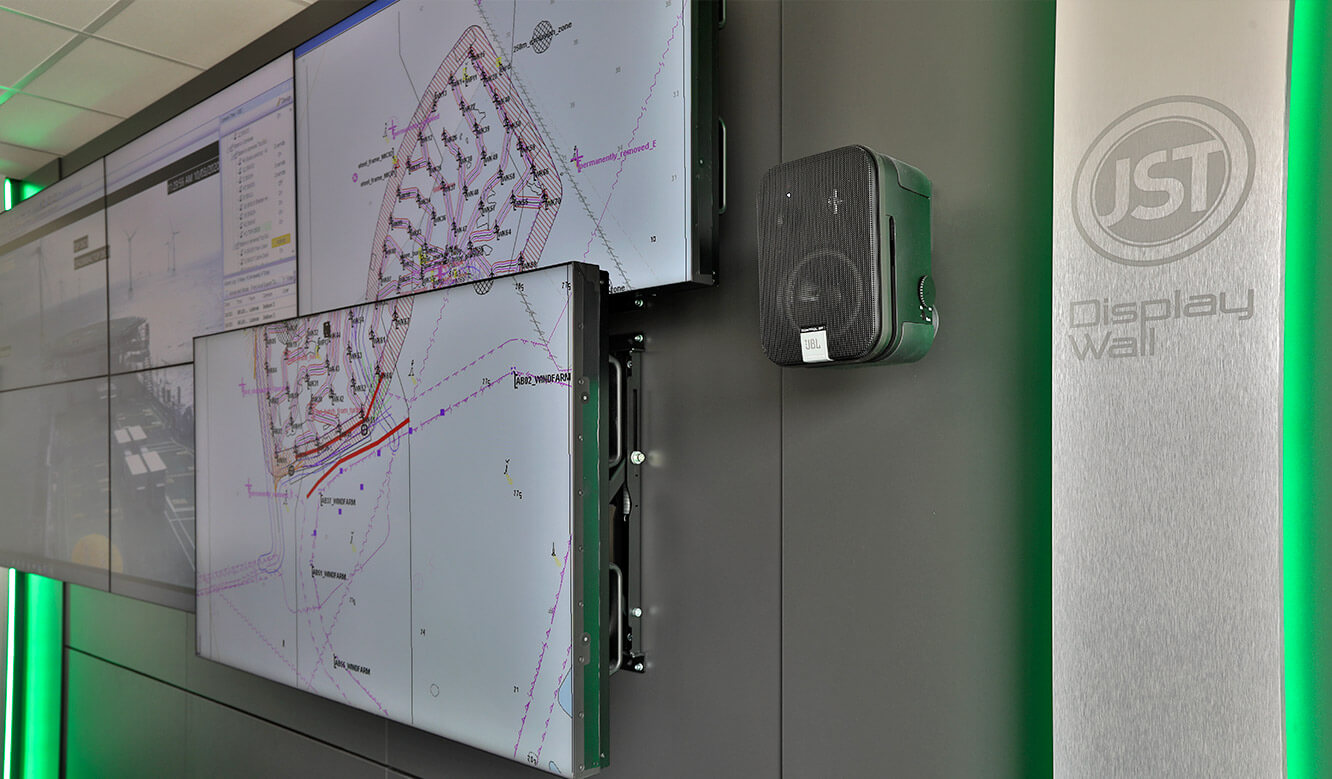

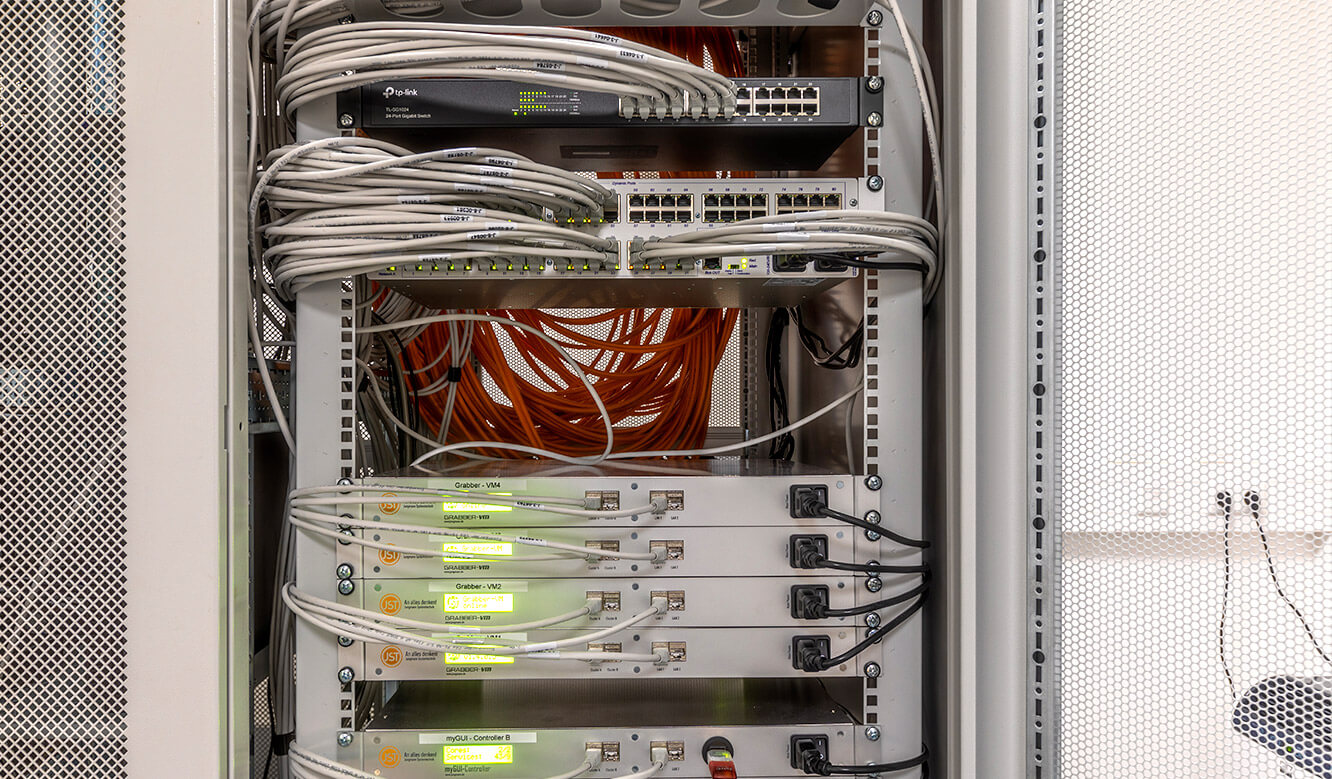

The MultiConsoling® from JST serves as the technical basis for the completely new control room on Rügen. A system that allows any source to be displayed in real time on workstation monitors, on individual displays in the video wall or as a BigPicture across several large display walls with just one keyboard-and-mouse unit – and all with just a few clicks. Marco Schwarmann: “This simple, intuitive control system is great. No employee needs to be specially trained for this. I can reach all my systems on the outsourced computers in the technical room with just a few key combinations and can work freely”.

Sea room and offshore substation in view

These various systems in the Viking Wind Farm control room include remote monitoring of the transformer platform, which has been designed redundantly for safety reasons, and control of the sea area in and around the wind farm. A new video wall with 24/7-optimised business displays enables operators to keep a constant eye on ship movements and give early warnings of possible “course deviations”.

Step by step to the perfect solution

Wind expert Schwarmann praises in particular the intensive cooperation with JST consultant Timo Bredehöft, who has been involved in the project from the very beginning: “During our first visit to the control room simulator , we were mainly concerned with the question ‘What is going on?’ After we had looked at and tried everything, we were able to approach a solution together, step by step. And by the end of the day, Mr. Bredehöft had already developed a concept for us that was ultimately 90 percent just like that – perfect!”.

Our references today (selection)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)