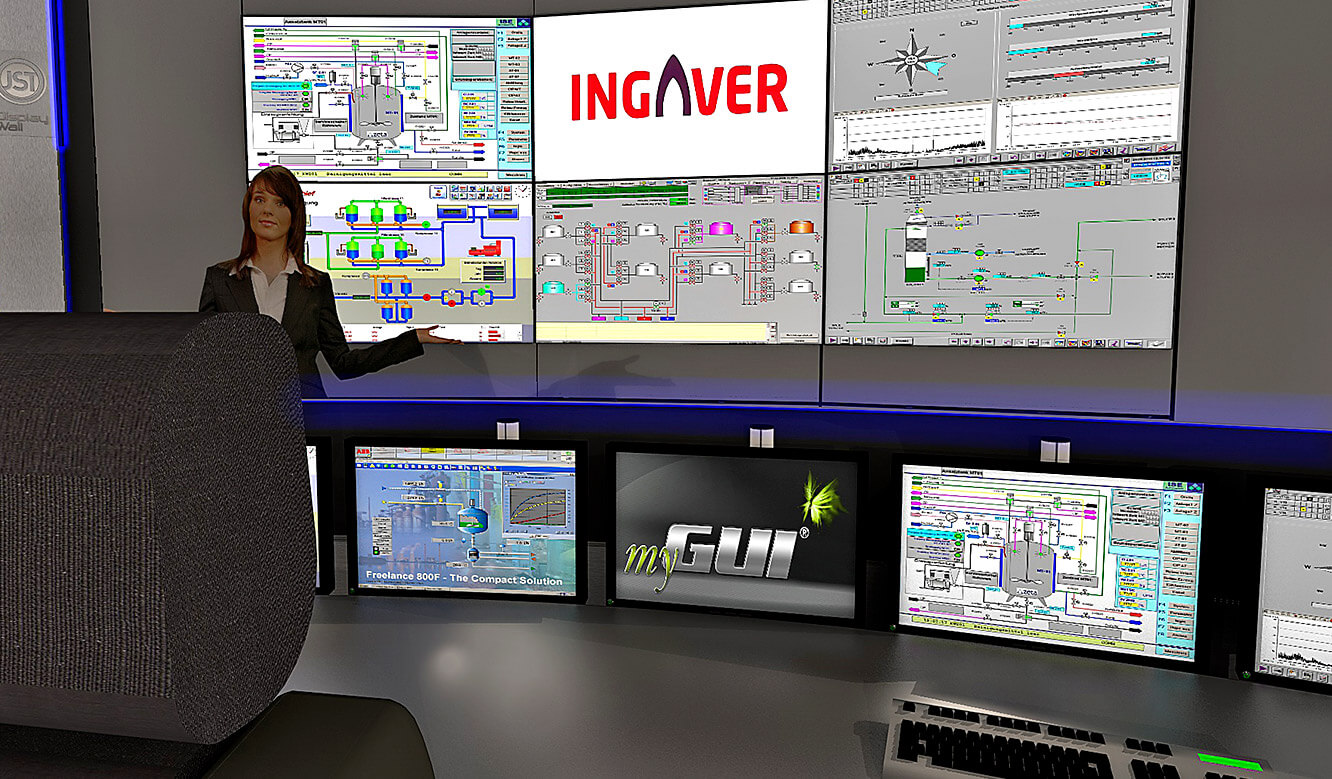

New energy control room puts competence at the center

A control room as the center of the energy supply at the site for the start of a new era. This is what makes the control center at the ArcelorMittal Bremen swb site so unique. Together with swb AG, ArcelorMittal Bremen has founded INGAVER (Innovative Gasverwertungs-GmbH). A joint venture with a total of 200 employees, for which the starting signal was given with the installation of the new central energy control room by the specialists from JST – Jungmann Systemtechnik®.

Four control rooms on a company site. Managed by two companies that cooperate with each other to optimise the energy supply for steel production on the Weser. What could be more obvious than an alliance? “In the past we have always been interested in close cooperation. That is why we are joining forces at this point”, explains INGAVER Energy Manager Thorsten Doege the joint path taken by swb and ArcelorMittal Bremen.

Central energy control room as a first step

As the first step of the new company, four distributed control rooms were combined into one central control room. From here, the operating team can organise and manage all energy media on site – such as electricity, water, technical gases and compressed air. swb CEO Dr. Torsten Köhne calls the merger and with it the new control room “an important step towards future-oriented sustainable steel production.”

Ergonomic requirements for technology and furniture

Technology and furniture in the new energy control room should also be “forward-thinking.” A requirement that the control room professionals at JST have fully met. Project manager Thorsten Doege comments: “Previously, each individual employee had to monitor around 20 screens arranged in two rows. Something urgently needed to be done.”

Workstation in control room with height-adjustable desk.

Individual adjustment possible at the workplace

The solution: large-display technology. Today, each operator uses six displays at his workstation and six more displays on the Video Wall. The ergonomics in the energy control room were additionally optimised by height-adjustable desks and special 24/7 chairs.

Representative control room

The employees also rate the INGAVER control room as thoroughly positive. They were involved in the planning at an early stage of the project. Made possible by virtual tours thanks to photo-realistic 3D plans, produced by the JST specialists.

Praise for quality of advice and cooperation

For the energy manager one thing is certain: “The cooperation with JST ran perfectly from the first visit to the control room simulator all the way up to its completion.”

New control room for INGAVER

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationOur references today (selection)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)