Hand in hand: electromobility and modern control station technology

Electromobility continues to gain momentum: One of the pioneers within the Volkswagen Group is the plant in Zwickau, Saxony. More than 9,000 people work at this multi-brand site. Currently, a total of five models of the Volkswagen, Audi and Seat brands are produced there. A sixth vehicle will be added shortly. The factory thus plays a key role in the Volkswagen Group through the complete conversion to electromobility. To ensure that all the wheels mesh in the background, the Zwickau-based vehicle manufacturer benefits from the experience of the control room experts at JST – Jungmann Systemtechnik®. The result: A control station that meets the high demands on technology and innovation.

“In the right place at the right time” – this could be the motto of the material control station at the Volkswagen plant in Saxony, which was technically and ergonomically equipped by Jungmann Systemtechnik for the requirements of the future. The central task of the operator team in Zwickau: materials management (MaWi), i.e. the planning and control of material movements within the factory.

Constant control of the automated processes

Michael Beier, the responsible sub-department head, sums up the importance of the control center with an illustrative example: “Volkswagen orders important modules for vehicle construction externally, for example a cockpit. As soon as these components arrive at the plant, we are responsible for ensuring that supplies are available as needed. These are largely automated processes, but they have to be constantly tracked.”

Every part of importance for the big picture

But what happens when monitoring of these processes cannot be performed due to a failure, when there are undetected deviations? “If a part is missing in a process as highly complex as vehicle manufacturing, the factory would stop,” explains Michael Beier. A scenario that can be ruled out thanks to state-of-the-art control station technology.

JST software takes over the active monitoring process

Analogous to the visionary electromobility products leaving the Zwickau plant, monitoring technology also meets the highest standards. Michael Beier cites one of the main positive effects of the new installation: “Whereas staff used to have to continuously check whether inventory was approaching a critical mark somewhere, the JST software now takes over active monitoring.”

Benefit through combination of essential components

This is made possible by combining different components. All necessary materials management systems can be flexibly called up with the intuitive MultiConsoling® control technology, both on the new large display wall and at the individual workstations. It is no longer necessary to keep a constant eye on the stock. The JST monitoring software takes over exactly this task.

Alerting - visual and event-controlled

Thanks to predefined reference values, the PixelDetection®software alerts the control station team as soon as there are any deviations. The entire operator team receives event-oriented visual signals via the AlarmLight, with which the ergonomic Stratos X11® control room consoles and the video wall are equipped. No alarm is lost anymore.

Intuitive handling of the control technology

The handling of the control technology also played a decisive role in setting up the MaWi control station. “We wanted to be able to map the different systems clearly and flexibly, without changing workstations,” reports Michael Beier “That’s exactly what we can now do with MultiConsoling®.” Another advantage: “In the past, the workstations had to be set up anew each time there was a shift change. Today, every user has his or her individual dashboard saved and can call up his or her desired arrangement in a flash,” says Beier. This is made possible by the JST CockpitView® software solution, which was developed by JST specifically for workstations that are used by different employees in shift operations.

"The future is ready. Get on board."

Conclusion for Michael Beier: “We have achieved significant improvements with regard to the quality of work – this is also supported by the feedback from colleagues.” And so the maxim of Volkswagen’s Zwickau site in Saxony now also applies “behind the scenes”: “The future is ready. Get on board.”

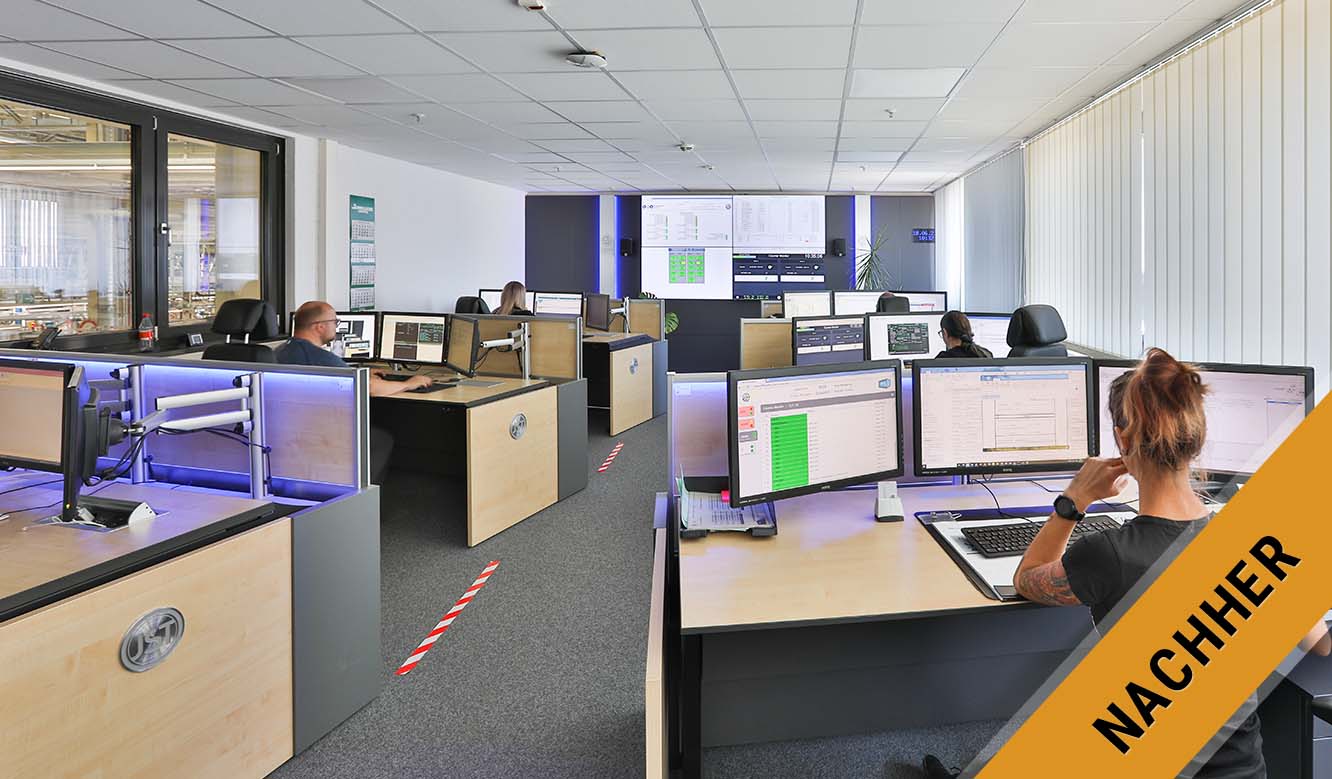

Control station before and after the conversion

Our references today (selection)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)