Production control center completely new equipped

The monitoring of around 2,000 computer systems is the focus of the employees at Audi’s so-called “MMS” control center in Ingolstadt. MMS – that stands for Manufacturing Management System. Behind this is the permanent testing of all steps that are necessary to produce the various models. The new control center was equipped by thecontrol room specialists from JST – Jungmann Systemtechnik®.

The JST professionals have already demonstrated their expertise in various major projects of the Audi Group. For example, in the “vehicle control” control center, which serves as a pilot control center within the company. Also the responsible persons of the control center of MMS have taken a close look at it. MMS project manager Jürgen Schneider on this: “This was a perfect reference for us. We are in constant communication with our colleagues there.”

Control station is the point of contact for production

As first-level contact for production of the Audi models A3, A4, A5 and Q5, the MMS team has a round-the-clock view of all systems for assembly, body shop and paint shop. Every component that is used for the individual cars is precisely displayed to the production staff. With more than 2,500 cars a day, a huge amount of information that needs to be monitored.

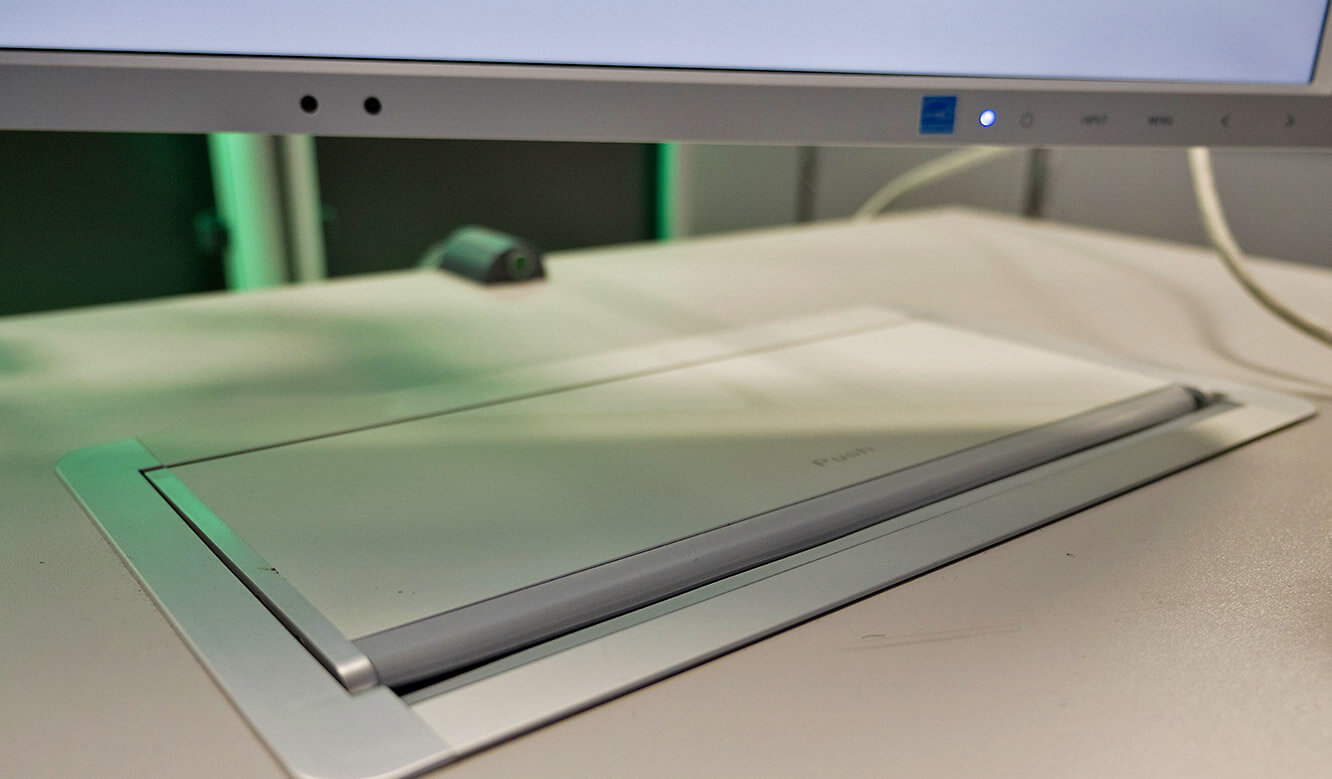

JST control center workplace: In the Audi control center, particular importance was attached to the ergonomic design of the workplaces . A task that JST was able to carry out as desired, thanks to years of experience.

The JST software makes response times shorter

Given the complexity of all this information, Jürgen Schneider values the technology installed by Jungmann. With the PixelDetection alarm software®, the operators in the control center are immediately informed via the new proactive large screen wall if a fault occurs anywhere. “The softwarehas the great advantage that the employees do not have to keep a permanent eye on all systems, but are proactively alerted to current events”, says Jürgen Schneider, “this not only provides noticeable relief, but also shortens response times”.

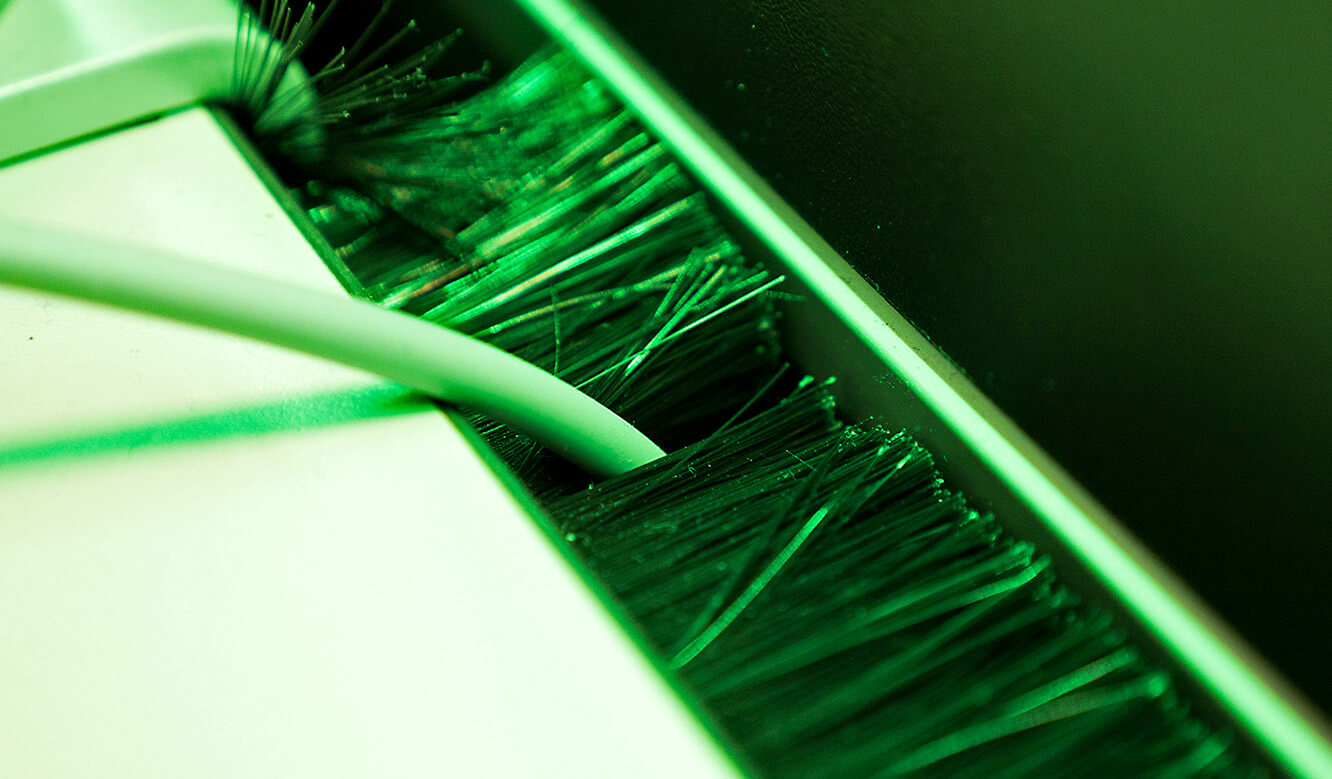

JST large display wall: The large display wall claddingis used for the decorative installation of the LC displays as well as for the acoustic and thermal insulation.

All relevant information on one dashboard

The project manager mentions another advantage that was realised with the JST equipment in the control center: “Thanks to the Software CockpitView®, we are able to combine a wide variety of systems and all relevant information on one interface as a complete view.

JST MultiConsoling®: The myGUI – shown here on the left screen – serves as a user interface for MultiConsoling®, with which it is possible to display any sources (computers, cameras, etc.) in real time on the workplace monitors, on individual large-screen displays or as BigPicture across several large-screen displays. Another special feature: Only one mouse and keyboard are needed for each workstation to operate everything in real time.

Great acceptance by the employees

The JST products are not only praised by those responsible for the project, but also by the control center staff, who appreciate the ergonomic advantages of height-adjustable Operator Desks, for example. “We involved the employees in the planning right from the start and the acceptance is correspondingly high,” says Jürgen Schneider, who mentions another benefit: By using JST MultiConsoling®– technology, it was possible to outsource the computers to a separate technical room. The result: significantly less exposure to noise and heat in the control center.

Our references today (selection)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)